About TITAN Wuxi

TITAN Metal Fabricators, Wuxi Co. Ltd., also known as TITAN Wuxi, is the premier resource for fabrication of Reactive Metal Process Industry Equipment in China.

TITAN Metal Fabricators, Wuxi Co. Ltd., also known as TITAN Wuxi, is the premier resource for fabrication of Reactive Metal Process Industry Equipment in China.

TITAN Wuxi designs and manufactures Heat Exchangers and Pressure Vessels for highly aggressive applications using the corrosion-resistant metals Tantalum, Niobium, Zirconium, Titanium and High Nickel Alloys.

TITAN’s core business is the expert design and fabrication of cost effective process equipment.

The company’s expertise is manufacturing these corrosion-resistant alloys:

- Titanium

- Tantalum

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Lean Duplex Stainless Steel

- Hastelloy®

- Zirconium

- High Nickel Alloys

- Monel®

Serving the corrosion-resistant specialty equipment needs of the Processing Industries:

- Chemical

- Pharmaceutical

- Steel Pickling

- Petrochemical®

- Oil & Gas

- Solar Power

- Bio Mass

- Nuclear Power

- Mining

- Water Desalination

- Liquefied Natural Gas

Trust and Expertise:

TITAN Wuxi provides its customers with world-class expertise in industry processes where corrosion control is mandatory. Long-term experience and the latest design innovations for your project:

- Heat Exchangers

- Pressure Vessels

- Piping

- Columns

- Condensers

- Dip Tubes

- Reactors

- Spargers

- Storage Tanks

Serving China, Asia and the World, TITAN Metal Fabricators, Wuxi represents the very finest in process equipment technology and manufacture.

TITAN Wuxi Design Capacities:

Diameter: 3.5 meters diameter (11.5 feet diameter)

Length: 50 meters ( 164 feet long)

Weight: 200t

Pressure: 100 Bar

Temperature: 650◦C

Larger equipment may be accommodated depending on specific shape and design

Manufacturing Certifications:

TITAN Wuxi’s pressure vessel fabrications fully comply with Chinese SELO requirements for installation of pressure vessels in China. It holds Manufacture License of Special Equipment (MLSE) and adheres to all applicable Chinese Pressure Vessel Standards.

Chinese GB Code – Pressure Vessel Code (Chinese)

ASME Code – ASME Section VII Division 1 (American)

Pressure Equipment Directive (European)

Material Selection:

The experts of TITAN Metal Fabricators Wuxi can help you determine the proper materials of construction for corrosives you face in your process. Our scope features the same breadth of material selection as in USA, featuring the reactive metals (Tantalum, Niobium, Zirconium, Titanium), and high nickel alloys (Hastelloy, Inconel, Monel, Duplex, Duplex Stainless Steels, etc.).

Transportation

Located approximately 150 km west of Shanghai, TITAN Wuxi offers easy access of major shipping facilities.

TITAN Metal Fabricators (Wuxi) Co., Ltd.

Our Company Heritage

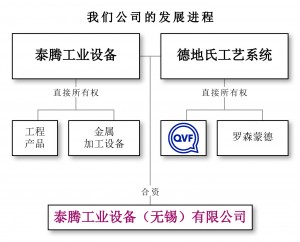

TITAN Wuxi is a joint venture between two of the most respected global process equipment manufacturers – TITAN Metal Fabricators, Inc., headquartered in Camarillo, California, USA, and De Dietrich Process Systems from Reichshoffen, France.

TITAN Metal Fabricators, Wuxi Co. Ltd. is directly supported from the International Headquarters and Principal Manufacturing Facility of TITAN Metal Fabricators in Camarillo, California, USA. Engineering, fabrication and quality control departments of both locations are managed by the same team of specialized experts in the field of reactive metal process equipment manufacture. World-wide quality is assured and supported by TITAN Metal Fabricators, recognized globally as the leading manufacturer of reactive metal process equipment.

De Dietrich Process Systems has more than 325 years of experience and long term relationships in the pharmaceutical and fine chemical industries. De Dietrich is comprised of the brand companies QVF, Rosenmund and De Dietrich, the synergies of which have afforded De Dietrich Process Systems to become one of the most comprehensive global suppliers of engineered systems, equipment and services for the fine chemical and pharmaceutical industries.

Learn more about our Joint Venture partners by visiting: